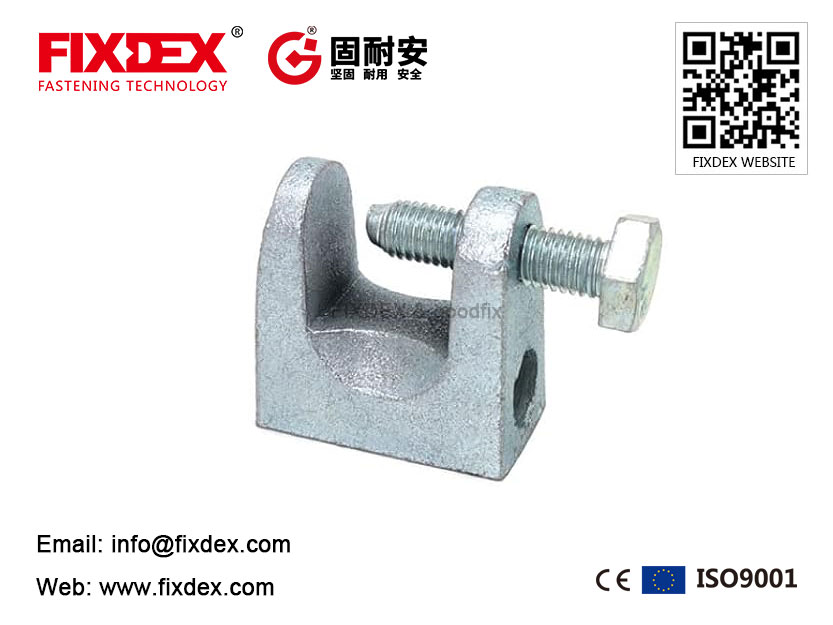

Beam clamps for knocking in Support Beam Clamp

1. What’s Support Beam Clamps?

A fastener China Beam Clamps is a tool that clamps objects by manual or electric force. It consists of two adjustable clamp arms, and the pressure is applied by rotating a screw or a pressure mechanism.Usually used with threaded rods Safety Beam Clamp are generally made of strong metal materials to ensure their stability and durability.

Read More: Catalog nuts

2. What types of Zinc Plated Beam Clamp are in FIXDEX&GOODFIX?

FIXDEX is China Beam Clamp Manufacturers produces Zinc Plated Beam Clamp with Spring Clamp, Quick Clamp, Side by Side Clamp, Angle Clamp

3. What are the functions and application fields of Clamp Support Beam or Tiger Clamp?

3.1 Carpentry:

Whether in making furniture, doors, windows, or other woodwork, Beam Clamp Formed Steel are an indispensable tool. They are used to clamp lumber and hold pieces of wood in place for processes such as cutting, drilling and assembling.

3.2 In metalworking, Beam C Clamp are used to hold metal workpieces for operations such as welding, milling, grinding and drilling. Their stability and adjustability make the working process more precise and safe.

3.3 Car maintenance:

Beam clamps are used to clamp and fix auto parts during auto maintenance. For example, when changing brake pads, adjusting engine parts, and repairing body parts, Zinc Plated Beam Clamp keep workpieces in place and help repairers run their repair jobs smoothly.

3.4 Mechanical manufacturing:

In the machinery manufacturing industry, Safety Beam Clamp are usually used to clamp mechanical parts to ensure the accuracy and stability of assembly. They help workers firmly connect different parts together to complete the manufacture of an entire mechanical assembly.

4. Correct use how to use of Support Beam Clamp or Safety Beam Clamp

4.1 Select the appropriate type and size of the tiger clamp to ensure that it can clamp the workpiece and provide sufficient stability.

4.2 Before using the Beam Clamps, check the clamp arm and screw rod for damage or looseness, and make sure its adjustment button or knob is available.

4.3 Make sure that the workpiece being clamped is in full contact with the clamp arm surface of the tiger clamp to avoid slipping or instability.

4.4 Use proper strength and speed to clamp the workpiece, avoid excessive pressure, so as not to damage the workpiece or the tiger clamp itself.

4.5 Pay attention to safety, avoid fingers caught between the clamp arms, and ensure that the workpiece is firmly fixed on the workbench or support.