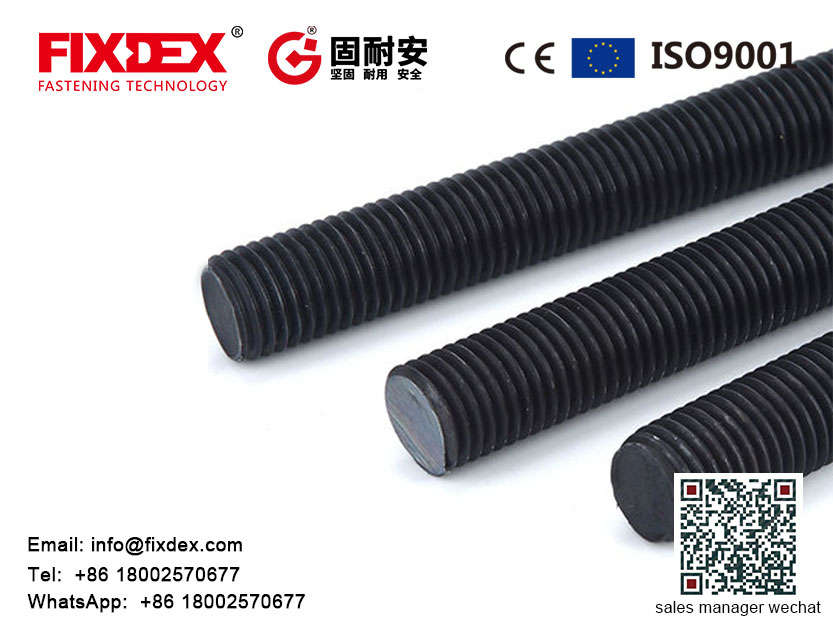

high quality ss304 ss316 full threaded rod/threaded bar/stud bolt supplier

high quality ss304 ss316 full threaded rod/threaded bar/stud bolt supplier

Read More: Catalog threaded rods

FIXDEX Factory2 ss304 ss316 full threaded rod/threaded bar/stud bolt

FIXDEX Factory2 ss304 ss316 full threaded rod/threaded bar/stud bolt workshop

How to identify the quality of stainless steel threaded rod/threaded bar/stud bolt?

1. Magnetic detection

You said stainless steel is magnetic, right! It is also true that it is not magnetic! In fact, they are essentially different. We all know that stainless steel is divided into austenitic stainless steel and ferritic stainless steel. Austenitic stainless steel is non-magnetic, while ferritic stainless steel is a strong magnetic steel. Through a series of experiments, it is proved that austenitic stainless steel will have subtle magnetism under certain special conditions, but it is non-magnetic under normal circumstances.

2. Conduct nitric acid point test

In many cases, it is difficult to distinguish the 200 series, 300 series, 400 series and other types of stainless steel with the naked eye. The nitric acid point test is the most intuitive test method to test the corrosion resistance of the substrate. Usually, the 400 series will only be slightly corroded during the test, while the 200 series stainless steel with the lowest corrosion resistance will have obvious corrosion marks.

3. Hardness test

If austenitic stainless steel will show some magnetism when cold rolled under atmospheric pressure, then the first magnetic test just mentioned is invalid; so we need to heat the stainless steel to about 1000-1100℃ and then water quench it to eliminate the magnetism of austenitic stainless steel and test the hardness. The hardness of austenitic stainless steel is usually below RB85

In addition

The hardness of 430, 430F and 466 steel is less than Rc 24

The hardness of 410, 414, 416 and 431 is Rc36~43

The hardness of high carbon 420, 420F, 440A, B, C and F steel is Rc50~60

If the hardness is Rc50~55, it may be 420 steel

The hardness of quenched 440A and B samples is Rc55~60

The Rc value of 60 or above is 440C steel.

4. Through machining inspection

If the stainless steel being tested is shaft-shaped, it is recommended to take it to a common lathe or CNC lathe for machining inspection, but there are still limitations. This method is only suitable for easy-to-cut steel and standard stainless steel, such as 303, 416, 420F, 430F, 440F. The type of steel is identified by the shape of the turning chips. This type of easy-to-cut steel will emit an unpleasant odor when turned in a dry state.

5. Phosphoric acid detection

This is a detection method that we use more often in daily life. This method is used to distinguish chromium-nickel stainless steel. Add concentrated phosphoric acid to 0.5% sodium fluoride solution and heat it to 60-66℃.

6. Detection by copper sulfate point

This method can detect ordinary carbon steel and stainless steel. The concentration of copper sulfate solution must be between 5% and 10%. When dropped on the steel to be tested, a layer of metallic copper will form on the surface of ordinary carbon steel within a few seconds, while the surface of stainless steel will basically remain unchanged.

7. Sulfuric acid solution detection

This method can distinguish 302, 304, 316, and 317 stainless steels. Prepare sulfuric acid with a concentration of 20% to 30% and a temperature of about 70°C, and put the steel to be tested into the solution. 302 and 304 stainless steels will produce a large number of bubbles when they encounter the solution and will turn black within a few minutes;

On the contrary, 316 and 317 stainless steels will not show a large reaction in the solution, and basically will not turn black within 10 to 15 minutes.

8. Cold acid point detection

The same type of stainless steel can be distinguished by dripping a 20% sulfuric acid solution on the surface of the sample that has been ground, polished, cleaned or roughly polished.

Drop a few drops of acid solution on the surface of each sample. Under the action of the acid solution, 302 and 304 stainless steels are strongly corroded and turn black, showing brown-black or black, and then green crystals are formed in the solution;

316 stainless steel corrodes slowly and gradually turns brown-yellow, then turns brown-black, and finally forms some light green black crystals in the solution; The above reaction of 317 stainless steel proceeds more slowly.

9. Observation through sparks

The spark test is used to distinguish carbon steel, structural alloy steel and tool steel, but it is of little use in distinguishing stainless steel. This spark test method can help experienced operators to classify stainless steel into four major categories, but it is not easy to distinguish between different steel grades.

The characteristic spark states of these four categories of stainless steel machines are as follows:

Class A: 302, 303, 316 steel, producing short red sparks with several forks.

Class B: 308, 309, 310 and 446 steel, producing very few short dark red sparks with several forks.

Class C: 410, 414, 416, 430 and 431 steel, producing long white sparks with several forks.

Class D: 420, 420F and 440A, B, C, F, producing shimmering colored sparks with obvious flashes or long white sparks.

10. Through hydrochloric acid detection

This detection method can distinguish 403, 410, 416, 420 stainless steel with low chromium content from 430, 431, 440, 446 stainless steel with high chromium content

Dissolve equal amounts of sample cuttings in a hydrochloric acid solution with a volume density of 50% for about three minutes, and compare the color intensity of the solution. The steel with a higher chromium content has a darker green color.