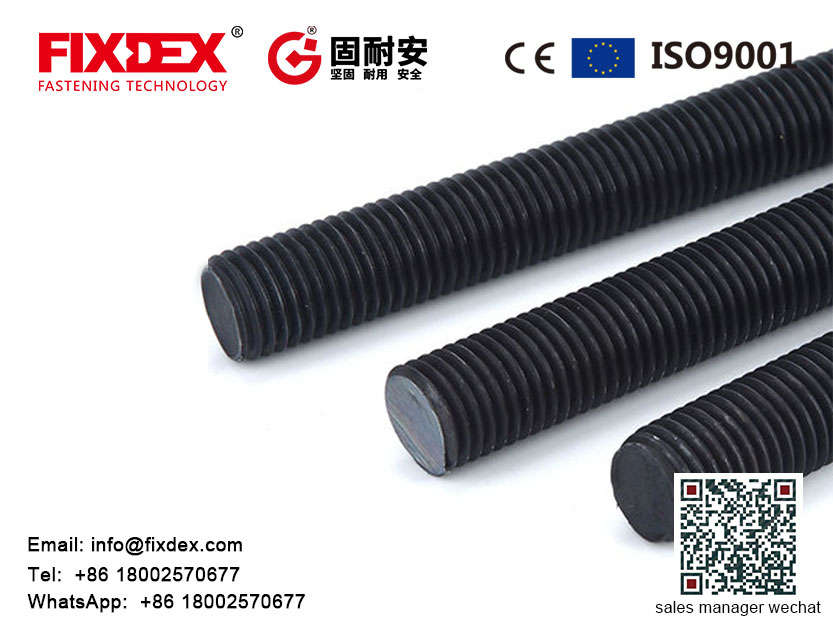

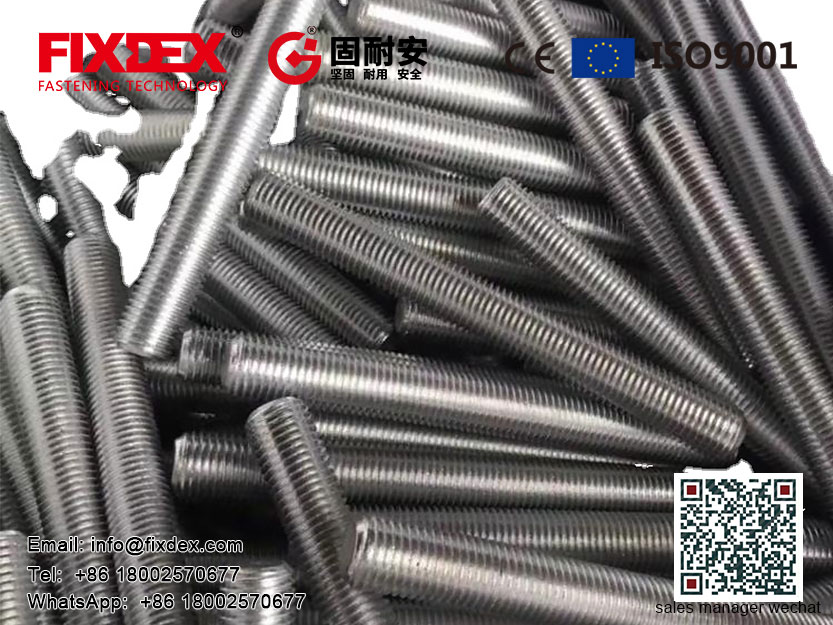

Manufacturer grade 12.9 stud bolt

Manufacturer grade 12.9 stud bolt

Read More: Catalog threaded rods

How to choose High Tensile Threaded Rod Zinc Plated?

grade 12.9 threaded rod Use Conditions

According to the specific application scenario, determine the mass of the load to be moved, the installation direction, the guide rail form, etc. These factors will directly affect the selection of the lead screw.

threaded bar specifications

Depending on the usage conditions, you can choose different specifications of 12.9 grade threaded screws, such as M8, M10, M12, etc., to ensure that the screw can meet the requirements of load and installation space.

Threaded rod and fixing accuracy and usage environment

According to the accuracy requirements of the application, select the appropriate accuracy level (such as C3 to C7), and consider the use environment (such as temperature, humidity, dust, corrosion, etc.) to determine whether special protective measures and lubrication methods are required. According to the use conditions, the ball screw is initially screened, mainly based on indicators such as basic dynamic rated load and allowable speed. The basic dynamic rated load refers to the axial load that the ball screw can withstand under certain conditions, while the allowable speed refers to the maximum safe speed of the ball screw. Verification selection: By calculating the allowable speed and selecting the appropriate motor, the stiffness verification and accuracy level verification are carried out to ensure the accuracy of the selection. In summary, when selecting a 12.9 grade threaded rod, it is necessary to comprehensively consider factors such as use conditions, specifications, accuracy and environment. By simplifying the calculation selection and verification selection, it is ensured that the selected ball screw can meet the needs of the application and has good performance and durability.