What bolts need to be inspected? bolt inspection methods

Quality inspection can be carried out from multiple aspects such as the finished bolt tensile load, fatigue test, hardness test, torque test, finished bolt tensile strength, bolt coating, depth of decarburized layer, etc. For fastener products in specific use occasions, it may be necessary to assess the performance of special indicators, or the indicators must meet requirements that exceed those specified in ordinary standards.

Strengthening the quality control of the raw materials used for fasteners is also a particularly critical step. Fasteners of different types and uses have different specific material requirements. No matter which material is used, the appropriate raw material must be selected according to the characteristics and performance requirements of the product.

How to reduce the substandard quality of fasteners?

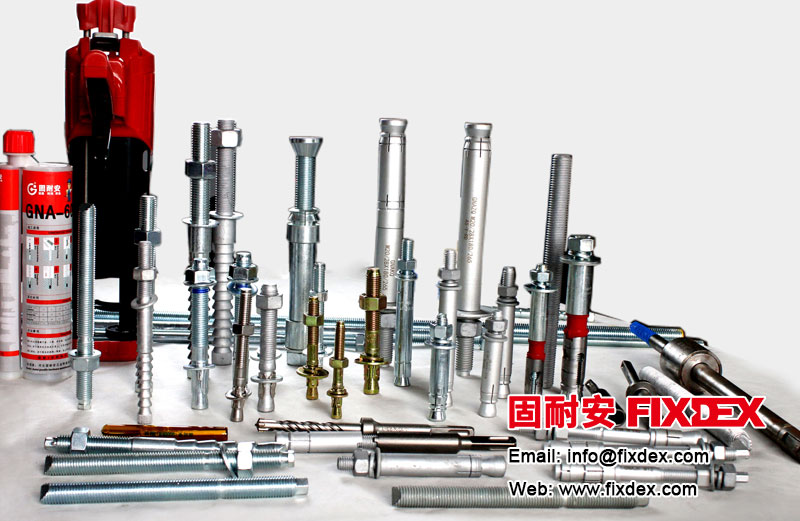

fasteners anchor bolts Quality inspection and control

In order to reduce a series of problems caused by fastener quality defects, scientific inspection of fasteners should be strengthened and scientific methods should be used to ensure the quality of fasteners. The quality inspection and control of fasteners should be based on reality. There are differences in the performance requirements of fastener products in different fields, and the specific implementation standards are different, so there should be different emphases in inspection.

Not only that, the other dimensions and geometric tolerances of high-strength bolts, nuts, and washers for steel structures are also different from the technical requirements of high-strength fasteners for wind power, which is also related to the surface treatment methods commonly used for high-strength fasteners for wind power.

Post time: Jun-26-2024