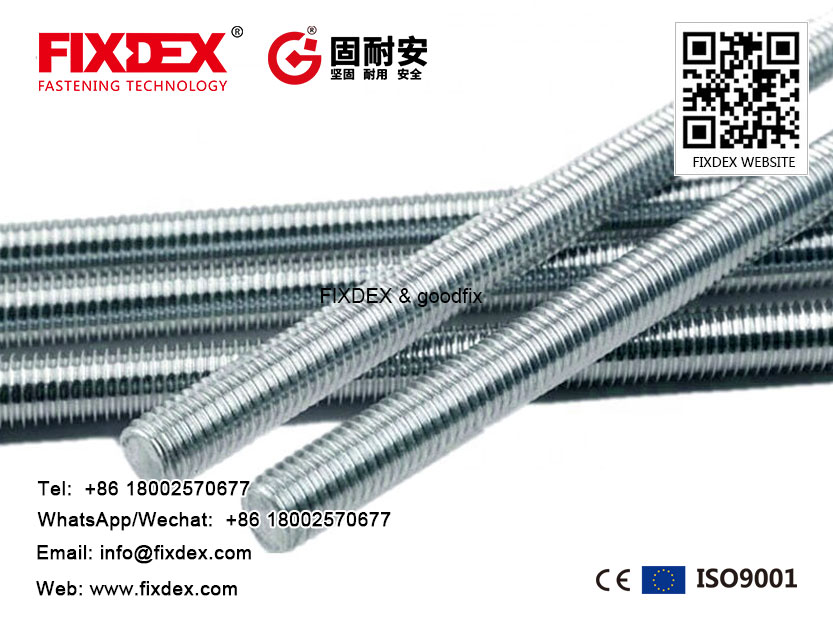

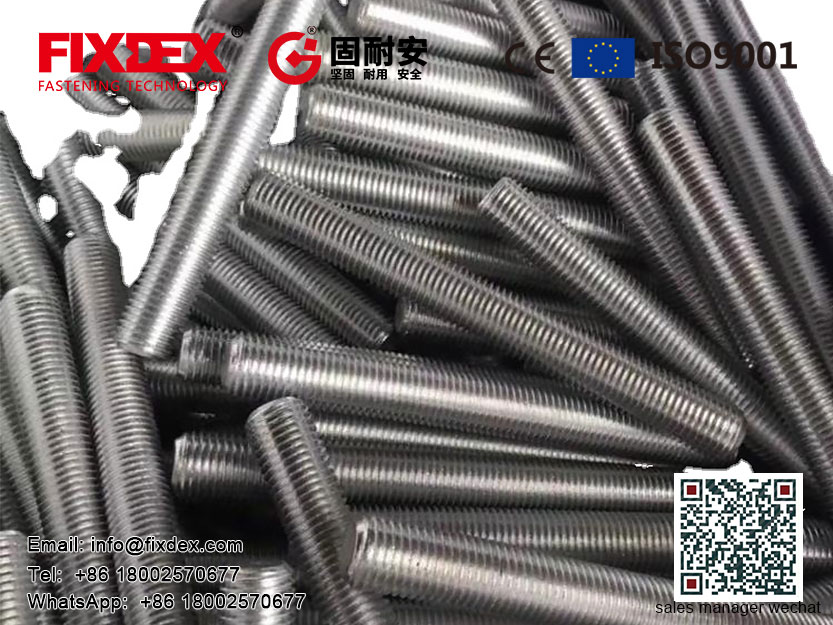

Umgangatho ophezulu we-SS304 i-SS316 ye-SS316 egcwele i-rod / i-threed bar / umthengisi we-bolt bolt

Umgangatho ophezulu we-SS304 i-SS316 ye-SS316 egcwele i-rod / i-threed bar / umthengisi we-bolt bolt

Funda ngokugqithisileyo:Ikhathalogu ikhutshiwe i-rods

Umzi-mveliso we-Filldex2 ss304 i-SS316 ye-SS316 ye-SSORERY STRY / I-BIR YOKUGQIBELA

Umzi-mveliso we-Filldex2 ss304 i-SS316 ye-SS316 egcweleyo / i-bar ye-Big / i-Bar Bolt Bolta

Ungawubona njani umgangatho we-stainess roo yentsimbi / i-bar edityanisiweyo / i-bolt ye-stud?

1. Ukufunyanwa kwemagnetic

Utshilo ngentsimbi engenanto, kulungile! Kukwayinyani ukuba ayingozibliki! Ngapha koko, zahlukile. Sonke siyayazi ukuba intsimbi engenanto yahlulwe yaba yintsimbi engathandekiyo yentsimbi engenasimo esingenasiseko. Intsimbi engenasimo ingenamazibuthe ayingelilo imagnethi, ngelixa intsimbi engenasimo ingenamazini eqinileyo. Ngothotho lweemvavanyo, kuyangqinwa ukuba intsimbi engathandekiyo i-Austititic iya kuba ne-chienenetism eqinileyo phantsi kweemeko ezithile ezithile, kodwa ayingeyonto yemagneti phantsi kweemeko eziqhelekileyo.

2. Yenza uvavanyo lwe-Nitric acid

Kwiimeko ezininzi, kunzima ukwahlulahlula-hlula kwama-200 eminye amazwe, kuma-300 ongcelele, ama-400 othotho kunye nezinye iintlobo zentsimbi engenasiseko kunye neliso elingenamehlo. Uvavanyo lwe-Nitric Acid Acid yeyona ndlela yovavanyo ye-wid yeyona ndlela iphakathi yokuvavanya ukumelana nokungasebenzi. Ngokwesiqhelo, izithotho ezingama-400 ziya kuhanjiswa kancinci ngexesha lovavanyo, ngelixa intsimbi engu-200 echumileyo kunye neyona nto iphantsi kweyona nto iphantsi kakhulu iya kuba namanqaku okhuseleko.

3. Uvavanyo lobunzima

Ukuba intsimbi engathandekiyo i-austenitic ingenazimpawu zinokubonisa ama-magnetism xa kubanda iqengqelwe uxinzelelo lwe-thamosmosfic, emva koko uvavanyo lokuqala lwemagneti lungasebenzi; Ke kufuneka sitshintshe intsimbi engenasigaba ukuya malunga ne-1000-1100 ℃ kwaye emva koko amanzi acekise ukuze asuse intsimbi engenasithamo kunye nokuvavanya ubunzima. Ubulukhuni bensimbi ye-austitic engapheliyo ihlala ingezantsi kwe-RB85

Ukwengeza

Ubunzima be-430, i-430f kunye ne-466 intsimbi ingaphantsi kwe-RC 24

Ubulukhuni be-410, 414, 416 kwaye i-431 yi-RC36 ~ 43

Ubulukhuni bekhabhoni ephezulu ye-420, i-420f, 440f, B, C kunye ne-F riel yi-RC50 ~ 60

Ukuba ubunzima yi-RC50 ~ 55, inokuba yintsimbi ye-420 yentsimbi

Ubunzima bokucinywa kwe-440A kunye ne-B Iisampulu ze-RC55 ~ 60

Ixabiso le-RC ezingama-60 okanye ngaphezulu liyintsimbi ye-440c yentsimbi.

I-4. Ngokuhlola uhlolo

Ukuba intsimbi engenasitayile ihlolwe i-shaft-imile, kuyacetyiswa ukuba ithathe inxaxheba kwi-lathe eqhelekileyo okanye i-CNC ye-CNC yokuhlola i-Mateling, kodwa kusekho umda. This method is only suitable for easy-to-cut steel and standard stainless steel, such as 303, 416, 420F, 430F, 440F. Uhlobo lwentsimbi luchongwe yimo ye-chips. Olu hlobo lwensimbi elula yokutsala iya kukhupha i-odor engathandekiyo xa iguqukile kwilizwe elomileyo.

I-5. Iphosphoric acid

Le yindlela echongiweyo esiyisebenzisa rhoqo kubomi bemihla ngemihla. Le ndlela isetyenziselwa ukwahlulahlula i-chromium-nickel yenqwaba. Yongeza i-phosphoric ye-phosphoric ehlanganisiweyo ukuya kwi-0.5% sodium yesodium fluoride kwaye uyitshise ukuya kwi-60-66 ℃.

I-6. Ukufunyanwa nge-Copper Sulfate Point

Le ndlela inokufumana i-carbon yentsimbi eqhelekileyo kunye nentsimbi engenasibala. Ukugxininiswa kwesisombululo se-sulfate yobhedu kufuneka kubephakathi kwe-5% ne-10%. Xa ihlile intsimbi ukuba ihlolwe, ungqameko lobhedu oluza kubakho kumphezulu wensimbi yekhabhoni eqhelekileyo ngaphakathi kwemizuzwana embalwa, ngelixa umphezulu wensimbi uya kuhlala ungaguqukanga.

I-7. Ukuchongwa kwesisombululo se-acid

Le ndlela inokwazi ukwahlula-hlulo 302, 304, 316, kunye ne-317 yezithambisi. Lungiselela i-sulfuric acid ene-20% ukuya kwi-30% kunye neqondo lobushushu elimalunga nama-70 ° C, kwaye ubeke intsimbi ukuba isetyenziswe kwisisombululo. I-302 kunye ne-304 izibetho ezingenantsingiselo ziya kuvelisa inani elikhulu leegubhu xa zidibana nesisombululo kwaye ziya kujika zimnyama kwimizuzu embalwa;

Ngokuchasene noko, i-316 kunye ne-317 izistithi aziyi kubonisa impendulo enkulu kwisisombululo, kwaye ngokusisiseko ayizukujika imnyama ngaphakathi kwemizuzu eli-10 ukuya kweli-15.

I-8. Ukuchongwa kwenqanaba le-acid

The same type of stainless steel can be distinguished by dripping a 20% sulfuric acid solution on the surface of the sample that has been ground, polished, cleaned or roughly polished.

Yilahle amathontsi ambalwa esisombululo se-asidi kumphezulu wesampulu nganye. Phantsi kwesenzo sesisombululo se-Acid, ama-302 nama-304 amathambo afakelwe ngamandla kwaye ajike emnyama, ebonisa imdaka, emnyama okanye emnyama, emva koko amakristali aluhlaza asekwe kwisisombululo;

I-316 i-corrodes yentsimbi engenasitali kancinci kwaye ngokuthe ngcembe ijika i-brown-tyheli, emva koko iguqukele emdaka-mnyama, kwaye ekugqibeleni yenza amakristali amnyama aluhlaza kwisisombululo; Impendulo engasentla ye-317 yentsimbi ihamba kancinci.

9. Ukujonga nge-Sparks

Uvavanyo lwe-spark lusetyenziselwa ukwahlulahlula i-carbon yentsimbi, intsimbi yesakhiwo sensimbi kunye nesixhobo sensimbi, kodwa ayisebenzi kangako ukwahlula intsimbi engenasigaba. Le ndlela yovavanyo ye-spark inokunceda abaqhubi abanamava ukuba bahlule intsimbi engenasibala kwiindidi ezine ezikhulu, kodwa akukho lula ukwahlula phakathi kwamabakala ahlukeneyo ensimbi.

I-spark eqhelekileyo kwezi ndidi zine zabanye oomatshini beentsimbi ezingenazitali zezi zilandelayo:

Iklasi A: 302, 303, 316 intsimbi, ivelisa iintlantsi ezimfutshane ezibomvu ngeefolokhwe ezininzi.

Iklasi B: 308, 309, 310 ne-446 intsimbi, ivelisa iintlantsi ezimbalwa ezibomvu ezimnyama ezineefolokhwe ezininzi.

Iklasi C: 410, 414, 416, 430 kunye ne-431 intsimbi, ivelisa iintlantsi ezimhlophe ezimhlophe ngeefolokhwe ezininzi.

Iklasi D: 420, 420f kunye ne-440F, B, C, F, ukuvelisa iintlantsi ezinombala ocacileyo okanye iintlantsi ezimhlophe ezibonakalayo.

I-10. Ngomsebenzi we-hydrochloric acid

Le ndlela yokufundiswa inokwazi ukwahlula-403, 410, 416, 420, i-420, i-431, 440, 446 inesitayile esiphakamileyo seChromium

Dibanisa izixa ezilinganayo zesampulu kwisisombululo se-hydrochloric acid nge-50% kangangemizuzu emithathu, kwaye uthelekise ubukhulu besisombululo. Intsimbi ene-chromium ephezulu ye-chromium inemibala eluhlaza eluhlaza.